Serving the Aerospace, Industrial and Medical Industries

Litron, Inc. is the leading U.S. supplier of laser welding, laser sealing and laser cutting services for aerospace, industrial and medical components. From Hi-Rel electronic microwave packages to class three medical implant devices, we're built to serve your most demanding needs.

Our facilities offer everything from state-of-the-art ISO Class 7 Clean Room environment for sealing in an inert environment to a full-service electronic package fabrication center complete with gold plating and feedthru integration services.

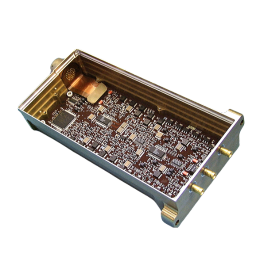

Precision Package Fabrication for Aerospace Components

For the Aerospace, Military and Government Contracts

Litron machines, laser welds and laser seals precision components for the aerospace industry. With conformance to MIL standards such as MIL-PRF-38534, MIL-STD-883, MIL-STD-202 Litron can handle the most exacting projects.

From the most straightforward to the most complex housing, Litron has the ability to machine and plate your microwave packages and integrate the feedthru's, as well as laser seal the lids; all to your specifications.

Each housing that leaves our facility is fully tested to some of the same standards they will be subjected to upon receipt at your facility. We know the packages we're fabricating meet the quality standards you demand.

Laser Hermetic Sealing of Microwave and RF Packages

After your microwave or RF packages have been manufactured and populated with electronic components, Litron is there to provide the laser hermetic sealing as well. We’ve built our facility to ensure your components are fully protected. Our ISO Class 7 cleanroom is equipped with state-of-the-art laser welding and sealing systems and testing centers for the final laser sealing of your components.

Materials Welded

Our lasers can weld a variety of materials from Aluminum and Kovar to Stainless Steel, Titanium, and Inconel to mention a few. If you’re not sure whether the material can be welded just let us know and we’ll tell you our experience and/or try a sample to demonstrate the weldability.

Gloveboxes

The Hermetics lab is equipped with top-of-the-line glovebox laser systems that were designed and assembled by Litron. Whether you need hermetic sealing in a Nitrogen/Helium or Argon/Helium atmosphere, our systems are setup for your part. With multiple vacuum bake ovens, we can have a variety of parts running through the process at the same time, allowing for quick turn-around to meet the most demanding schedule.

Testing Capabilities

All the microwave and RF packages that are sealed in our Hermetics lab are visually inspected prior to welding and fine leak checked and sometimes gross leak checked after welding based on customer specifications. All testing is done within the cleanroom environment, so your parts are never exposed to an uncontrolled environment.